Gear Shaping: Precision Crafted to Meet Extreme Standards

At the heart of mechanical motion and transmission, gear shaping stands as a testament to human ingenuity and technical prowess. It is an intricate procedure, demanding a commitment to precision, advanced technology, and a deep understanding of material science.

Gear shaping, in its essence, is a machining process that creates accurate and detailed gear teeth profiles. This technique employs a cutting tool, known as a shaping cutter, that performs a reciprocating motion along the length of the gear blank. Each stroke of the cutter delicately removes material to progressively form the gear teeth.

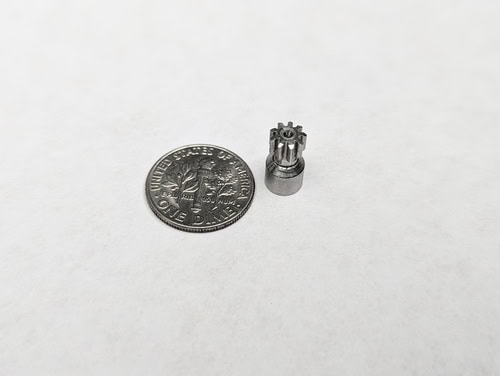

Our expertise in gear shaping is the epitome of precision engineering. We employ state-of-the-art machinery, combined with an in-depth understanding of metallurgy and material behavior, to produce gears of unmatched accuracy. We take pride in our ability to maintain tight tolerances – reaching up to a few micrometers – across various gear types and sizes. This meticulous approach is in response to the modern world’s demand for flawless gear operation across myriad applications, from automotive transmissions to complex aerospace systems.

For us, the phrase “close enough” has no place in our vernacular. We understand that a minute error in gear shaping can lead to a significant decrease in gear performance and, potentially, failure in the larger mechanical system. That’s why we work relentlessly, optimizing our processes and innovating our methodologies to meet and exceed the most stringent quality standards.

Precision gear shaping finds is critical in a range of applications that demand the highest levels of precision and reliability. High-performance automobiles, aerospace equipment, heavy-duty machinery, and advanced robotics are just a few fields that leverage our services. In these applications, the tolerance for error is minimal, and the requirement for accuracy is paramount. Inconsistent gear shaping can lead to decreased performance, increased wear and tear, and shortened gear life, resulting in high repair and replacement costs.

American Precision Gear rises to these challenges, delivering gears shaped with precision down to the smallest detail. Our process ensures exceptional contact patterns, minimal backlash, optimized noise levels, and outstanding load distribution, thus maximizing the efficiency and life of the gear.

In a world that demands perfection, we are your partners in precision gear shaping. Let’s shape the future together.